“ALL INVENTED, DESIGNED AND PRODUCED IN 37 MQ STUDIO IN MUNICH”

ANDREA MOCELLLIN | FOUNDER & INVENTOR, REVOLVE AIR

"IT ALL STARTED IN 2014"

| 100+ 3D MODELS |

| 10+ PHYSICAL PROTOTYPES |

| 2 RAPID PROTOTYPE MACHINES |

"REINVENT A TIMELESS PRODUCT WITH THE NEEDS OF TODAY"

Andrea Mocellin created the original patented design for the folding wheel in 2015.

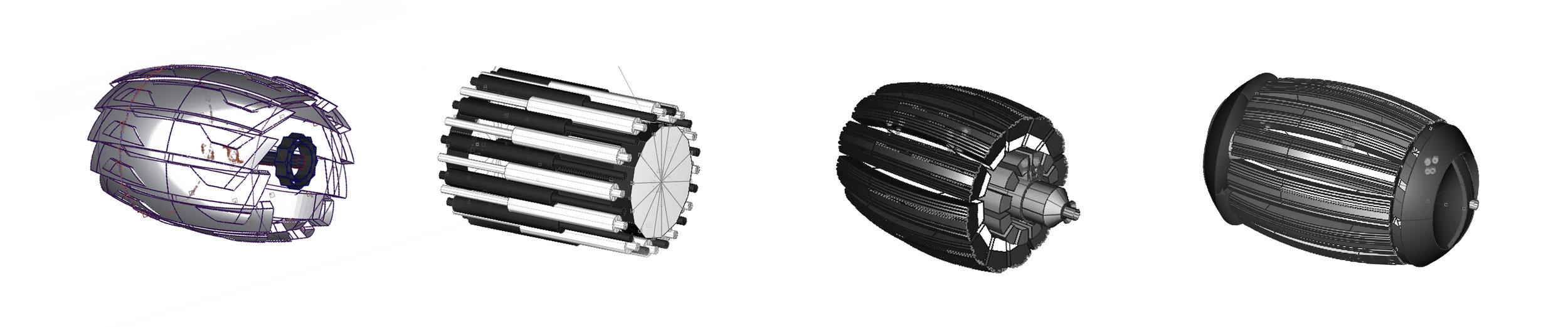

The patented mechanism is been reach after years of several hundred 3D models and dozens of physical prototypes in order to get the most efficient and accurate folding mechanism. The mission was to build the most compact wheel ever made. Timeless foldable products, robotics, universal joints and Omni wheel for their extremely modular and timeless functional design inspire its creation.

BRAINSTORMING AND FORM RESEARCH

Analyzing form and function to achieve the best compromise between mechanism and aesthetics.

HOBERMANN PRINCIPLE STUDIES

A Hoberman sphere is an isokinetic structure capable of folding down to a fraction of its normal size by the scissor-like action of its joints.

RAPID PROTOTYPE TESTING

Developing the most effective mechanism through the use of several rapid prototype models. Verifying solidity and feasibility of Revolve.

PATENT PENDING

"A FOLDABLE WHEEL AND VEHICLES EQUIPPED WITH SUCH A WHEEL"

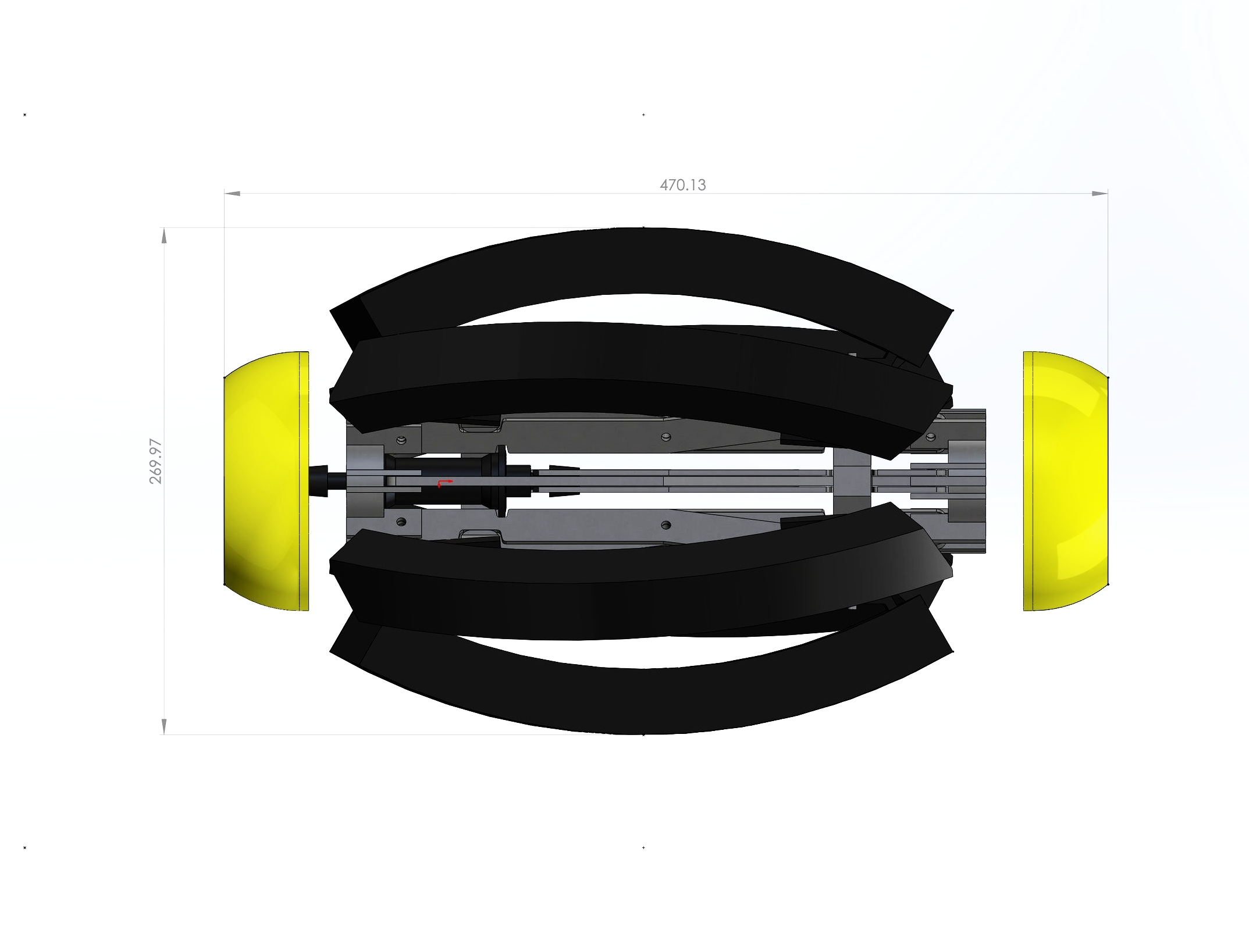

Foldable wheel including a double hub, a rim with rubberised sectors, and spokes pivotly connecting each hub with the sectors of the rim. The sectors of the rim can be figured, starting from an extended condition of forming the wheel in which the hubs are mutually approached, in a collapsed condition in which the hubs are mutually spaced apart along the wheel axis. The spokes are pivoted to the hubs substantially on the wheel axis and in the collapsed condition the sectors of the rim extend longitudinally between the two hubs.

"SUITABLE FOR ALL TYPES OF TROLLEY OR CART WITH THE HELP OF SIDE WHEELS"

"VEHICLES EQUIPPED WITH SUCH A WHEEL"

"THE CHALLENGE TO CHANGE A TIMELESS PRODUCT"

THE UNIVERSAL WHEEL, A TIMELESS PRODUCT NEVER CHANGED IN SHAPE AND FUNCTION

"THE NEED OF EXPLORATION"

THE WHEEL HAS ALWAYS BEEN THE BEST COMPANION IN EXPLORING NEW SPACES

OMNI WHEEL

Omnidirectional wheels are poly wheels, similar to Mecanum wheels, are wheels with small discs around the circumference which are perpendicular to the turning direction. The effect is that the wheel can be driven with full force, but will also slide laterally with great ease.

GUARDBOT

Guardbot can operate in many demanding situations, as it can travel on paved road, off-road, sand, snow, sloped surfaces, and in water, where it can navigate upstream. Guardbot is designed for mission operations in broadcasting, surveillance, security, and detection.

AIRLESS TIRE

Non-pneumatic tires (NPT), or Airless tires, are tires hat are not supported by air pressure. They are used on some small vehicles such as riding lawn mowers and motorized golf carts. Tires composed of closed-cell polyurethane foam are also made for bicycles and wheelchairs.

LUNAR WHEEL

The tire is made of a woven mesh of zinc-coated piano wire to which titanium treads were riveted in a chevron pattern. This pattern kept the wheels from sinking into the soft lunar soil. The lunar soil proved harder than expected and the wheel treads left tracks about half an inch deep.

STUDIES ON FORM AND FUNCTIONALITY

SERIES OF 3D MODELS TO ACHIEVE THE BEST COMPACTNESS AND ICONIC SHAPE OF FOLDED WHEEL

PROPORTION AND ERGONOMICS

MODULAR SIDE WHEELS USED TO ACHIEVE THE BEST PORTABILITY AND USABILITY ON BOTH TROLLEY AND CART

ENGINEERING 3D STUDIES

STYLING DEFINITION

3D model used to define style and ergonomics.

UNFOLDED DESIGN

3D research to develop the right geometry.

COMPACT DESIGN FORM

Achieving the best compact configuration and usability.

STYLE AND DETAILS DEFINITION

HANDMADE PROTOTYPE

First working prototype to study solidity and usability of Revolve.

FEASIBILITY PROTOTYPE

Rapid prototype model used to verify feasibility and reduce the number of components.

FUNCTIONAL PROTOTYPE

Fully working prototype for testing locking and unlocking mechanism to minimize space when folded.

FINAL PROTOTYPE

Final prototype with all smooth finish, fully working in most of bicycle and wheelchair designs.

FULLY WORKING PROTOTYPE TESTED ON BOTH BICYCLES AND WHEELCHAIRS

A perfect representation of what Revolve will look like in our streets.

"AN OPEN STORY FOR THE PRESENT AND THE FUTURE OF THE FOLDABLE VEHICLES"

TO BUILD A BETTER MOBILITY WITH THE DEMANDS OF TODAY AND TOMORROW